Precision Built Into Every Project

Wagler's Quality Control

Precision Built Into Every Project

Wagler's Quality Control

We Lead with a

robust inspection protocol

to deliver superior outcomes.

Precision Built Into Every Project

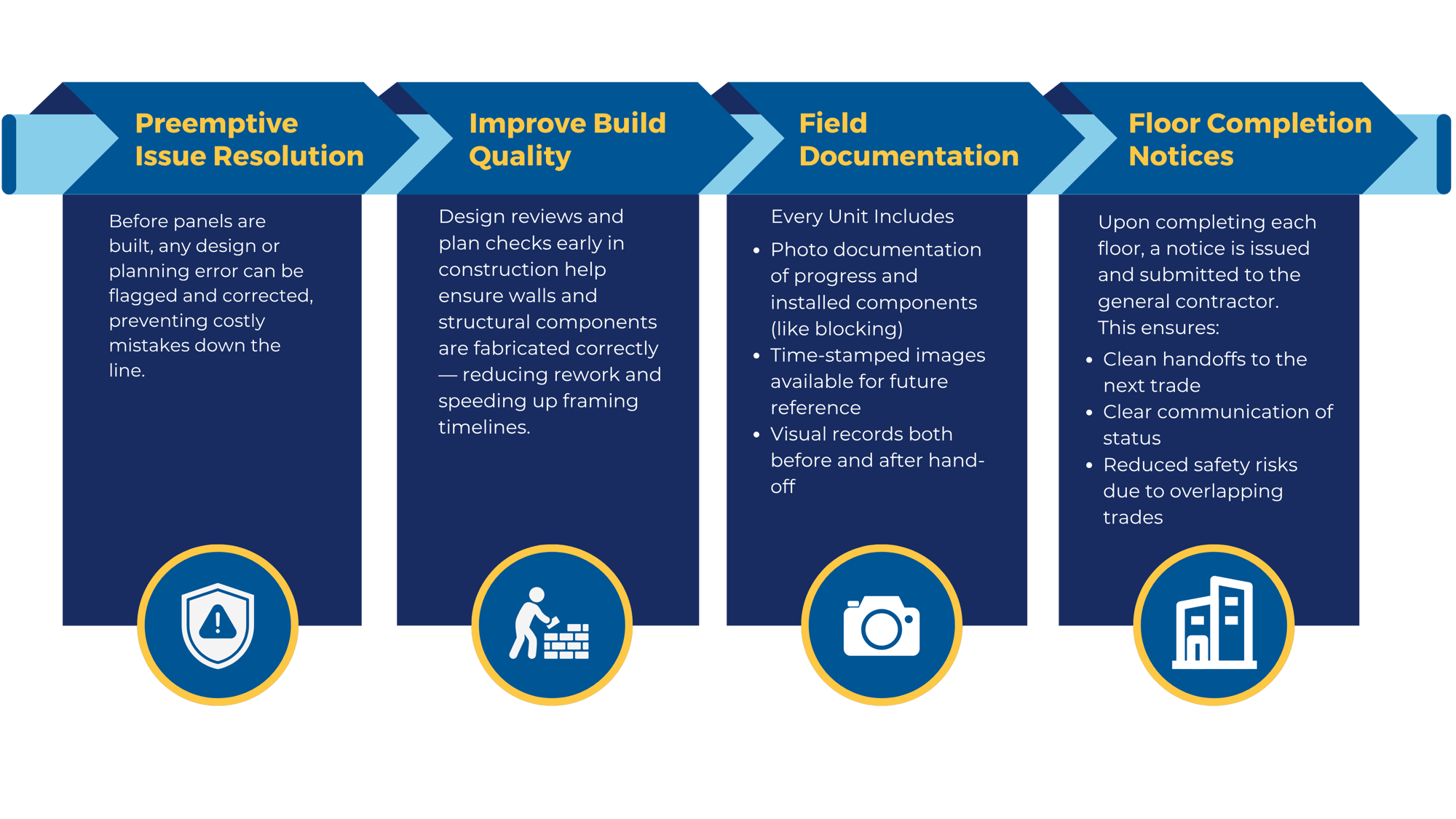

Why Our 32-Point QC System Matters

Our QC program bridges the gap between office planning and on-site execution. It ensures that:

Project managers and field crews are aligned

![]() Design and production errors are caught early in construction

Design and production errors are caught early in construction

Project managers and field crews are aligned

![]()

Design errors are caught before construction

![]()

Every unit is inspected and documented for accountability

The QC process holds Wagler and its subcontractors accountable.

If an error did make it to the job site, by catching it early, additional floors and buildings won't be impacted by the same error.

We’ve seen massive improvements in project quality because when our QC Manager identifies a field issue, it’s instantly visible to project managers in the office.

Key Benefits of

Our Quality Control Program

Inside the 32-Point Inspection Protocol

Every detail matters. Our inspectors document and verify critical elements in each unit — catching issues early, ensuring precision, and protecting your schedule.

How the 32-Point QC Program Works

Why Clients Choose Wagler

General contractors trust Wagler because we consistently deliver:

-

Clean, accurate framing

-

Transparent documentation

-

Fewer delays and callbacks

-

Safer job sites

-

Professional handoffs between trades

With our 32-Point QC Program, you're not just getting labor — you're getting a process designed for excellence from start to finish.

Discuss your project today!

We'd love to connect with you...

Please answer the questions below, and we will contact you to discuss your project.